Behind the scenes in coffee-growing regions, where specialty coffee is grown with passion, lies the art of identifying defects and imperfections in the beans. This guide explores the importance of this skill in the quest for exceptional quality. Every cup of coffee is a work of art, and the careful removal of defects is what allows the distinct flavors to shine through. In this guide, we’ll dive into the journey of identification, exploring common defects, grading processes, and practical techniques. Together, we’ll discover how dedication to identifying defects elevates specialty coffee to new heights of excellence.

1- Why Defects Identification is Crucial

Imagine savoring a fine wine but with a strange, unpleasant taste permeating every sip. In the same way, a coffee bean with a defect can damage the entire batch. Identifying defects is crucial because

- Impact on Flavor and Aroma: Defects in the beans can introduce unwanted flavors and strange aromas to the coffee. From bitter notes to musty flavors, these imperfections detract from the sensory experience that specialty coffees provide.

- Uniformity of Quality: The pursuit of excellence requires consistency. The presence of defective beans affects uniformity, resulting in variations in taste and quality between cups.

- Coffee Value: The quality of coffee is intrinsically linked to its value. Defective beans reduce the value of the lot and can negatively affect prices and the coffee’s recognition on the market.

- Producer reputation: Specialty coffee producers build reputations over time. Defective beans can damage this reputation, affecting the confidence of buyers and consumers.

- Consumer Satisfaction: Coffee quality is the basis of customer satisfaction. By eliminating defects, producers ensure that consumers enjoy every cup without disappointment.

- Sustainability: The effective identification of defects reduces waste since bad beans don’t reach the end consumer. This contributes to a more sustainable approach to coffee production.

Defect identification is a skill that turns a producer into a curator of experiences. It is a process of continuous improvement, where dedication to improving the final product results in lasting rewards. By removing imperfections, producers pave the way for nuances and flavor profiles to stand out, captivating the senses of coffee lovers. Therefore, identifying defects is not just a stage in production, but a commitment to excellence that permeates every bean and cup of specialty coffee.

2- Common Defects and Imperfections

Black grains: Black grains are one of the most easily identifiable defects. They occur when the grain is overripe, too dry or suffers from fungal infections. These beans tend to have bitter, unpleasant flavors.

Burnt grains: Burning occurs when the grains are exposed to high temperatures during the drying process. This results in a burnt, unpleasant taste in the coffee.

Broken beans: Broken beans are characterized by an uneven, rough surface. This can be caused by physical damage during harvesting or processing. These beans have a tendency to create an uneven cup of coffee.

Malformed beans: Malformed beans can be deformed or underdeveloped, often due to poor harvesting practices. They affect the uniformity of the coffee and can result in an uneven roast.

Damaged beans: Physical damage, such as cracks or breaks in the beans, are common defects. They can occur during harvesting, drying or transportation and can result in bitter flavors in the coffee.

Fermented beans: Unwanted fermentation during processing can result in beans with an unpleasant taste and aroma. Identifying fermented beans is crucial to maintaining coffee quality.

Green Beans: Beans that have not matured properly or have been picked prematurely are green and have a bitter, herbaceous taste.

Chemically Defective Beans: Chemical contamination, such as beans that have come into contact with chemicals or pesticides, can be harmful to health and must be identified and removed.

3- The Coffee Grading Process

The grading process is a synchronized dance of observation, analysis and separation. It plays a fundamental role in guaranteeing the quality of specialty coffee. Here are the steps involved:

- Selective harvesting: Selective harvesting is the first step in guaranteeing high-quality beans. Only mature and healthy beans are picked, eliminating the possibility of maturity-related defects.

- Pre-cleaning: After harvesting, the grains are pre-cleaned to remove dirt, leaves, and debris. This makes it easier to identify defects later.

- Density sorting: Grains of different densities are sorted using sieves and specific equipment. This helps to eliminate less dense and defective grains.

- Visual inspection: At this stage, the grains are inspected manually. Experienced observers examine each kernel, identifying visual defects such as black, sprouted, and malformed kernels.

- Tactile inspection: In addition to visual inspection, tactile analysis is crucial. Broken, cracked o, or abnormally textured grains are identified by touch.

- Use of technology: Some producers use advanced technologies, such as color sorting machines and electronic sensors, to identify defects efficiently.

- Separating the grains: Based on the visual and tactile inspection, the grains are separated into different categories, such as “perfect grains”, “grains with slight defects” and “defective grains”.

- Separate storage: The grains are stored separately according to their quality. This allows each batch to be roasted and processed properly.

The Importance of Grading:

The grading process is the guarantee that only the best beans will reach the cup. It ensures uniform quality, prevents the contamination of good beans by defective ones, and allows each batch to be treated in a personalized way to highlight its characteristics.

4- Grading Table

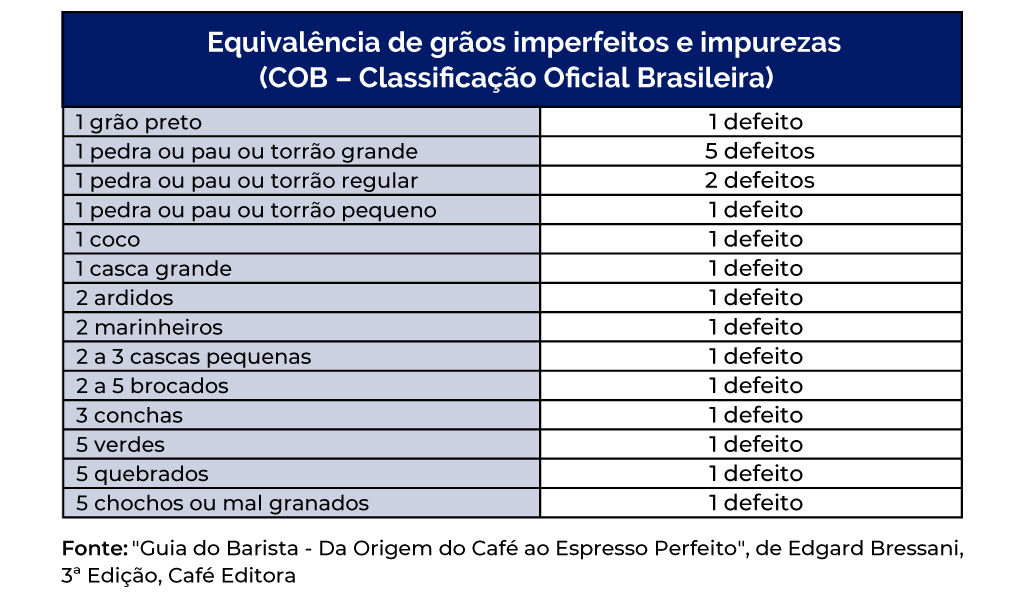

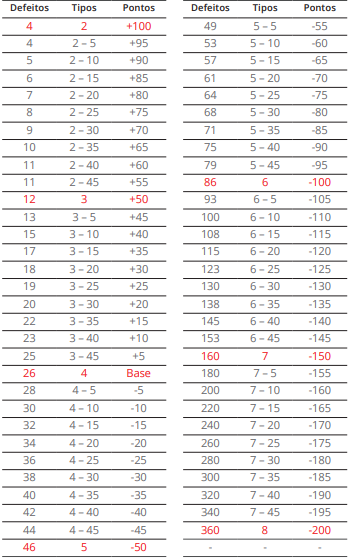

The coffee industry uses standard classification tables that list the types of defects and assign points to each one. The more serious the defects, the more points are awarded. For example, a black bean may be rated with more points than a sprouted bean.

- List of defects: The grading tables begin by listing the different types of defects that can be found in coffee beans. This can include defects such as green beans, black beans, fermented beans, sprouted beans, and broken beans, among others. Each type of defect is described clearly and in detail.

- Defect Score: For each type of defect listed in the table, a score is assigned. This score is usually based on the severity of the defect and how much it affects the quality of the coffee. More serious defects receive a higher score, while less damaging defects receive a lower score.

- Sample evaluation: During the grading process, coffee evaluators carefully examine the coffee samples and identify the defects present in each sample.

- Counting and Scoring: The graders count how many defective beans of each type are present in the sample. They then use the scores assigned in the table to calculate the total defect score for that particular sample.

- Defect equivalence: The total defect score is often converted into a metric known as “defect equivalence”. This is done by adding up the scores of all the defects identified. The higher the total defect score, the higher the defect equivalence and the lower the perceived quality of the coffee.

- Final Classification: Based on the defect equivalence, the coffee sample is classified into a quality category. These categories can vary depending on the specific classification table but generally range from high-quality categories, such as “special”, to lower-quality categories, such as “commercial”.

Grading tables provide a standard way of assessing and communicating coffee quality between different parts of the industry, such as producers, buyers, and roasters. This helps ensure consistency in the assessment of coffee quality throughout the production and marketing process.

5- Sorting and Separation Techniques

Sorting and separation are key processes for eliminating defective grains. Here are some of the techniques used:

- Manual Sorting: Skilled producers use manual sieves to separate grains based on size and density. This helps eliminate smaller and lighter grains, which are often defective.

- Density Sorting: Sieves with different openings allow grains to be sorted by density. Denser grains sink, while defective or less dense grains float.

- Ventilation: The use of air currents to remove husks and light fragments of grain is an effective technique. This also helps to eliminate unwanted particles.

- Floating in Water: Grains are placed in water, where defective grains float and are separated from healthy grains, which sink.

- Gravity Table: Grains are fed onto an inclined table. The difference in density causes the defective grains to move faster, allowing them to be separated.

- Magnetic Separation: This technique is used to remove metallic impurities from the grains.

Importance of sieving and separation techniques:

Sieving and separation techniques allow producers to eliminate defective beans and guarantee uniform quality. This is essential for the production of specialty coffee, where each batch must be consistent and free of imperfections.

As we delve deeper into identifying defects, we discover that every little detail matters. Sifting methods, careful separation, and good production practices are all essential ingredients for creating an unforgettable coffee experience. Each discarded bean is a statement of commitment to quality and an affirmation that perfection is a constant pursuit.

So, to those of you who are committed to perfecting your skills in identifying defects in specialty coffee beans, remember that you are part of a global tradition of quality and dedication. With every cup you savor, know that it is the result of hard work and a shared passion for creating something truly exceptional.